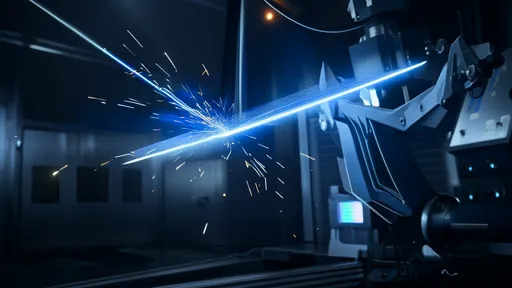

In an era where precision manufacturing dictates industrial competitiveness, a groundbreaking technology is quietly transforming how we cut and shape materials. Acoustic vibration cutting, or sonic wave material separation, represents a paradigm shift from traditional mechanical cutting methods. This innovative approach harnesses the power of precisely calibrated sound waves to achieve clean, energy-efficient cuts across various materials with micron-level accuracy.

The fundamental principle behind this technology lies in matching specific resonant frequencies to the molecular structure of target materials. When the applied sonic frequency aligns perfectly with a material's natural vibration characteristics, it creates concentrated stress points that facilitate exceptionally clean separation. Unlike conventional sawing or laser cutting which rely on brute force or thermal energy, this method works through controlled vibrational energy transfer at the atomic level.

Industrial applications are already demonstrating remarkable results. Aerospace manufacturers report 40% reduction in material waste when cutting titanium components using resonant frequency methods compared to water jet systems. The automotive industry has adopted sonic cutting for composite materials where delamination was previously a persistent challenge. Medical device producers particularly value the technology for creating burr-free edges on implantable components without heat-affected zones.

What makes this approach truly revolutionary is its dual benefit of precision and sustainability. Traditional cutting methods often require lubricants or generate significant thermal waste, whereas sonic separation operates cleanly at room temperature. The energy requirements are substantially lower since the process works with the material's inherent properties rather than overcoming them through force. Early adopters report energy savings exceeding 60% for certain applications while simultaneously improving cut quality.

The technology's development stems from decades of research in materials science and acoustical engineering. Modern computational modeling allows engineers to predict a material's vibrational response with extraordinary accuracy before physical cutting begins. Advanced sensors provide real-time feedback to maintain optimal frequency alignment throughout the cutting process, automatically adjusting for material inconsistencies that would compromise traditional methods.

Implementation challenges remain, particularly for extremely thick materials or those with highly irregular internal structures. The current generation of sonic cutting systems performs best on materials up to 100mm thickness, though researchers are making rapid progress extending these limits. Another consideration is the initial capital investment, which remains higher than conventional systems despite the long-term operational savings.

Looking ahead, the integration of artificial intelligence promises to unlock new capabilities in adaptive frequency control. Machine learning algorithms can analyze material feedback during cutting operations to optimize frequency parameters in real-time, potentially allowing the technology to handle an even broader range of materials with varying densities. Some laboratories are experimenting with multi-frequency approaches that could simultaneously target different molecular bonds within composite materials.

The environmental implications of this technology could prove as significant as its precision advantages. By dramatically reducing material waste and energy consumption in manufacturing processes, sonic cutting aligns perfectly with global sustainability initiatives. Several government research agencies have begun funding programs to accelerate adoption in heavy industries where the environmental impact of traditional cutting methods is most pronounced.

As the technology matures, we're seeing the emergence of hybrid systems that combine sonic vibration with minimal mechanical guidance for certain applications. These systems offer the precision of acoustic separation with the flexibility to handle more complex geometries. The next five years will likely see sonic cutting move from specialized applications to mainstream manufacturing as the cost-benefit equation continues to improve.

For quality control engineers, this technology brings unprecedented consistency to production lines. The non-contact nature of sonic cutting eliminates tool wear variables that plague mechanical systems, while the absence of heat prevents material property changes that complicate thermal processes. Early quality reports show dimensional tolerances improving by an order of magnitude in some applications.

The medical field presents particularly exciting possibilities. Researchers are developing surgical tools based on the same principles that could allow for ultra-precise tissue separation with minimal collateral damage. While medical applications require extensive testing and approval, preliminary studies suggest frequency-specific cutting could revolutionize certain delicate procedures.

From an economic perspective, the long-term savings potential is driving rapid adoption despite higher upfront costs. Manufacturers report payback periods as short as eighteen months when factoring in material savings, energy reduction, and quality improvements. As the technology scales and becomes more widely available, these economic advantages will only increase.

Workplace safety represents another often-overlooked benefit. Sonic cutting systems eliminate many hazards associated with traditional methods - no flying debris, reduced noise pollution (despite the sonic nature of the technology), and elimination of dangerous cutting fluids. Several manufacturers have reported significant reductions in workplace injuries after implementing the technology.

As we stand on the brink of this manufacturing revolution, it's clear that sonic cutting technology will redefine our approach to material processing. The combination of precision, efficiency, and environmental benefits creates a compelling case for widespread adoption across industries. Within the next decade, what began as a specialized laboratory technique may well become the standard against which all other cutting methods are measured.

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025