The textile industry stands on the brink of a technological revolution as plasma-based waterless dyeing emerges as a sustainable alternative to traditional coloring methods. This innovative approach, known as gas ionization coloring, harnesses the unique properties of plasma to achieve vibrant hues without consuming vast quantities of water or generating toxic runoff. Laboratories across Europe and Asia report unprecedented success in binding pigments at the molecular level using fourth-state matter, potentially rendering obsolete the centuries-old practice of boiling fabrics in chemical baths.

How Plasma Dyeing Works

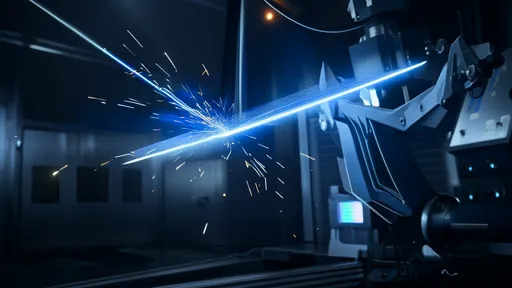

At its core, the process involves creating a partially ionized gas - plasma - within specialized vacuum chambers. When textile substrates are introduced, the energized particles interact with fiber surfaces at nanometer scales, altering their molecular structure to receive dye compounds. Unlike conventional methods requiring multiple rinsing cycles, the plasma-treated fabrics exhibit near-instantaneous pigment absorption rates exceeding 92% in recent trials. The German Institute for Plasma Technology recently demonstrated how wool fibers dyed with this method showed superior colorfastness after 50 industrial washes compared to conventionally treated samples.

Environmental Advantages Coming Into Focus

The ecological implications are staggering. A single pair of jeans typically consumes 7,000 liters of water during traditional dyeing - equivalent to one person's drinking water for seven years. Plasma coloration eliminates this entirely while reducing energy consumption by an estimated 40-60%. Perhaps most crucially, the closed-loop system prevents the discharge of carcinogenic azo dyes and heavy metals currently poisoning waterways in textile manufacturing hubs like Bangladesh. Early adopters including outdoor apparel brands report eliminating 18 metric tons of chemical waste per production facility annually.

Challenges in Industrial Scaling

Despite promising lab results, significant hurdles remain before widespread adoption becomes feasible. The current generation of plasma reactors can only process fabric widths of 1.2 meters - far below industrial standards requiring 3-meter-wide treatments. Moreover, achieving consistent coloration across natural fiber variations continues to challenge engineers. Dr. Elena Kovac from the Vienna Textile Research Center notes: "Cotton's unpredictable surface topography causes uneven plasma dispersion that manifests as streaking in finished products. We're developing predictive algorithms to adjust ionization parameters in real-time."

The Fast Fashion Dilemma

Ironically, the technology's greatest obstacle may be fast fashion economics. While plasma dyeing reduces long-term costs, the initial infrastructure investment ranges from $12-18 million per facility - a tough sell for brands operating on razor-thin margins. However, sustainability-focused luxury labels are leading the charge. Stella McCartney's recent collaboration with plasma tech startup DyeZero resulted in a 100% water-free handbag collection that sold out within hours despite 30% premium pricing.

Scientific Breakthroughs on the Horizon

Recent advancements suggest the technology may soon surpass conventional methods in versatility. Researchers at Hong Kong Polytechnic University successfully created plasma-induced nanostructures that produce structural coloration - essentially mimicking butterfly wing physics to generate colors without pigments. Meanwhile, a Swiss team has developed atmospheric plasma jets that could potentially allow for continuous roll-to-roll processing rather than batch treatments. These innovations might address both quality and throughput concerns simultaneously.

Regulatory Landscapes Adapting

Governments are beginning to incentivize the shift. The EU's upcoming Sustainable Textiles Strategy includes tax credits for waterless dyeing adoption, while China has classified plasma textile technology as a "national priority research area." Even in traditionally slow-moving industries, the combination of environmental pressures and consumer demand appears to be overcoming inertia. Fast Retailing (Uniqlo's parent company) recently announced plans to convert 30% of its dye houses to plasma systems by 2028.

The Human Factor

Workforce retraining presents another critical consideration. Traditional dye masters spend decades mastering color formulations through aqueous chemistry - their expertise doesn't directly translate to plasma physics. Educational institutions from Milan to Mumbai are launching specialized certification programs, but industry veterans warn the transition could displace thousands of skilled workers unless comprehensive retraining initiatives are implemented alongside technological deployment.

As dawn breaks on this textile revolution, the promise extends beyond environmental benefits. Plasma dyeing enables previously impossible color effects - from deep multidimensional blacks to chromatic shifts responding to body heat. When paired with digital design systems, it allows for instant color changes without cleaning massive dye vats between batches. The question is no longer if this technology will transform the industry, but how quickly manufacturers can adapt to its disruptive potential while ensuring equitable transition for workers entrenched in traditional methods.

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025